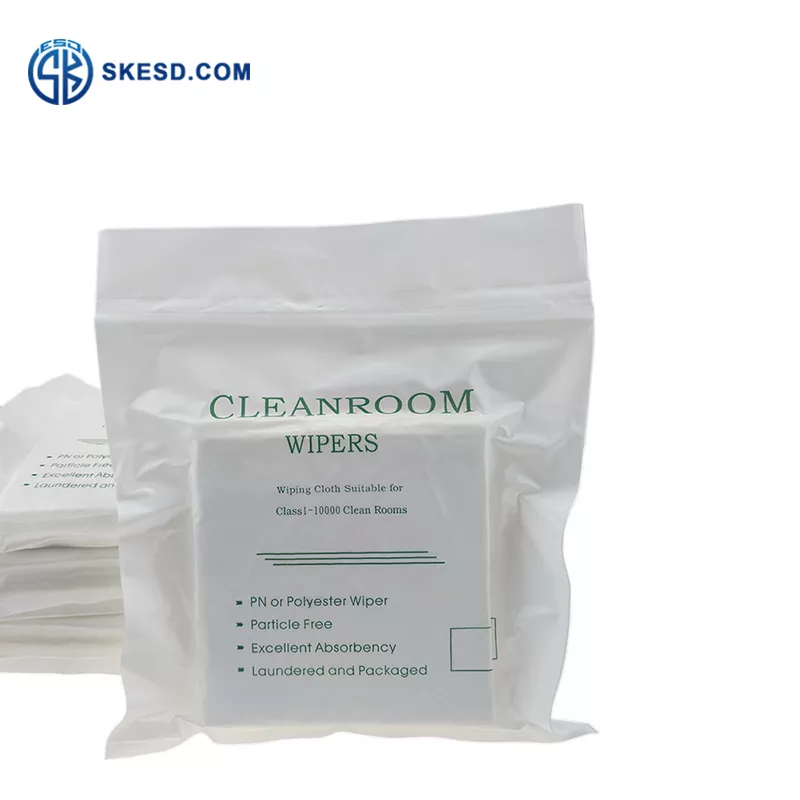

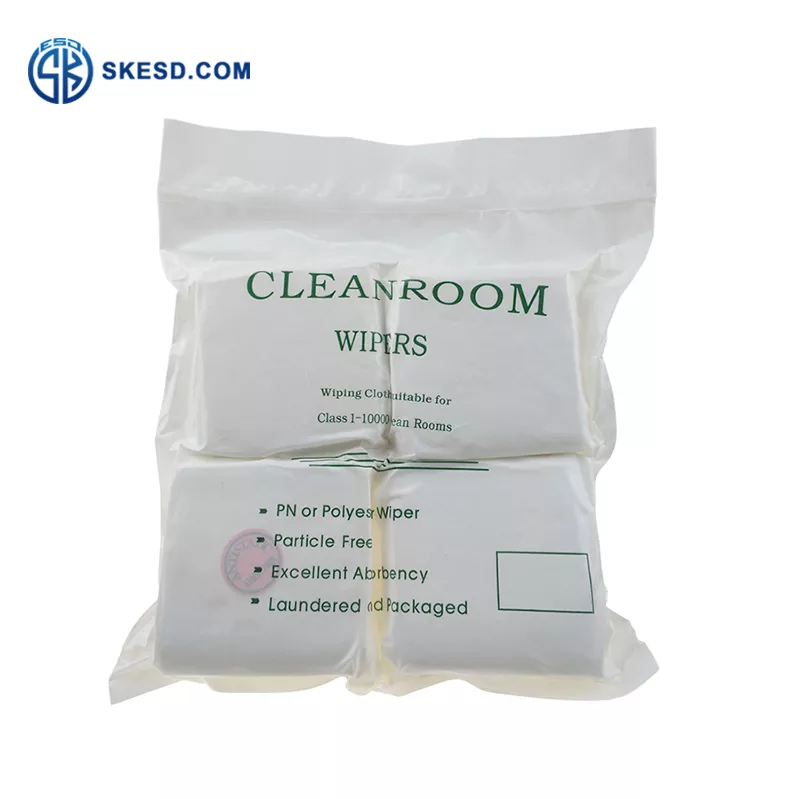

Cleanroom wipes are essential tools used in controlled environments to maintain cleanliness and prevent contamination. These specialized wipes play a crucial role in industries such as pharmaceuticals, biotechnology, electronics, healthcare, and aerospace, where maintaining a sterile environment is of utmost importance. In this comprehensive guide, we will explore the various applications of cleanroom wipes, their benefits, and why they are vital in ensuring cleanliness and safety.

Cleanroom Wipes for Surface Preparation and Cleaning

Cleanroom wipes are specifically designed to effectively remove contaminants from surfaces in controlled environments. They are made from high-quality materials such as polyester, polypropylene, or a blend of synthetic fibers that provide excellent absorbency and low particle generation. These wipes are engineered to have low levels of lint, static charge, and chemical residue, making them ideal for sensitive applications.

Cleanroom Wipes for Spill Cleanup and Maintenance

In cleanroom environments, spills can occur, posing potential risks of contamination. Cleanroom wipes come to the rescue in such situations, as they are capable of absorbing and containing spills effectively. These wipes are available in various formats, including pre-saturated with cleaning solutions or dry wipes to be used with compatible cleaning agents. They are also available in different sizes and configurations to meet specific spill cleanup requirements.

Cleanroom Wipes for Equipment Cleaning and Maintenance

To maintain optimal performance and prevent contamination, equipment in cleanrooms needs regular cleaning and maintenance. Cleanroom wipes are widely used for this purpose, as they are designed to be non-abrasive and gentle on delicate surfaces. Whether it’s removing dust, oils, or other residues, these wipes provide a safe and effective solution without damaging the equipment.

Cleanroom Wipes for Sterile Environments

In industries such as pharmaceuticals and healthcare, maintaining sterility is critical. Cleanroom wipes are extensively used in sterile environments to wipe down surfaces, equipment, and instruments. These wipes undergo rigorous testing and validation processes to ensure they meet the stringent standards required for sterile applications. They are often packaged in sterile, airtight containers to preserve their cleanliness until they are needed.

Cleanroom Wipes for Controlled Environment Manufacturing

In industries like electronics and semiconductors, where precision and cleanliness are paramount, cleanroom wipes play a vital role in the manufacturing process. They are used to remove contaminants, fingerprints, and other particles from delicate components, ensuring the quality and reliability of the final product. Cleanroom wipes contribute to reducing defects and improving yield in controlled environment manufacturing facilities.

Cleanroom Wipes for Personal Hygiene and Safety

Cleanroom wipes are not only used for cleaning surfaces and equipment but also for personal hygiene and safety. In cleanroom environments, where operators must wear protective clothing, cleanroom wipes are used to clean hands, gloves, and other exposed body parts to minimize the risk of contamination. These wipes are gentle on the skin while effectively removing dirt, oils, and particles, promoting a safe and hygienic working environment.

Conclusion:

Cleanroom wipes are indispensable tools in maintaining cleanliness and preventing contamination in controlled environments. Their versatile applications span across various industries, including pharmaceuticals, biotechnology, electronics, healthcare, and aerospace. From surface preparation and spill cleanup to equipment maintenance and personal hygiene, cleanroom wipes ensure a sterile and safe working environment. By utilizing these specialized wipes, industries can uphold the highest standards of cleanliness, minimize risks, and safeguard the integrity of their products and processes.

Related Products:

continue reading