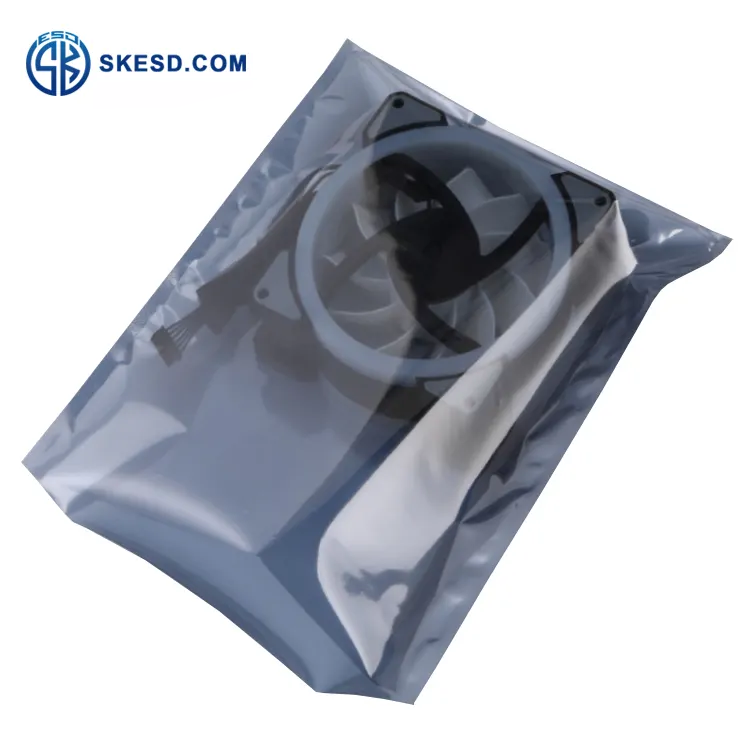

Anti Static Container is a specialized storage solution designed to protect sensitive electronic components, devices, or materials from electrostatic discharge (ESD).

Anti static containers are available from, in a comprehensive range of sizes. They provide a versatile and economical method for storage and handling. With their semi-open front storage design, the LF series are extremely sturdy and robust. They can be integrated easily into all shelving systems. Their standard sizes mean that they can be used in any combination within shelf units, independent of the application. Most also have integrated fixings on the rear to allow them to be used with louvre wall panels giving extra flexibility.

Product Details:

Anti static containers are using the PP composite material from our independent research and de-velopment。

Anti static plastic containers are designed and manufactured according to in-dustrial standards.

Anti static storage containers are both rigid and tough, not easily damaged intransit.

Anti-static containers have a permanentanti-static effect.

Beside the traditional ESD black color, the natural color ESD plastic products can be provid-ed, such as blue, green, yellow and red,More environmental protection and better quality.

Feature :

1. It is tough and wear resistant, moistureproof, heat insulation and shockproof, static electricity. It is widely used in the loading, packing, storage and transportation of electronic components and products in the production process.

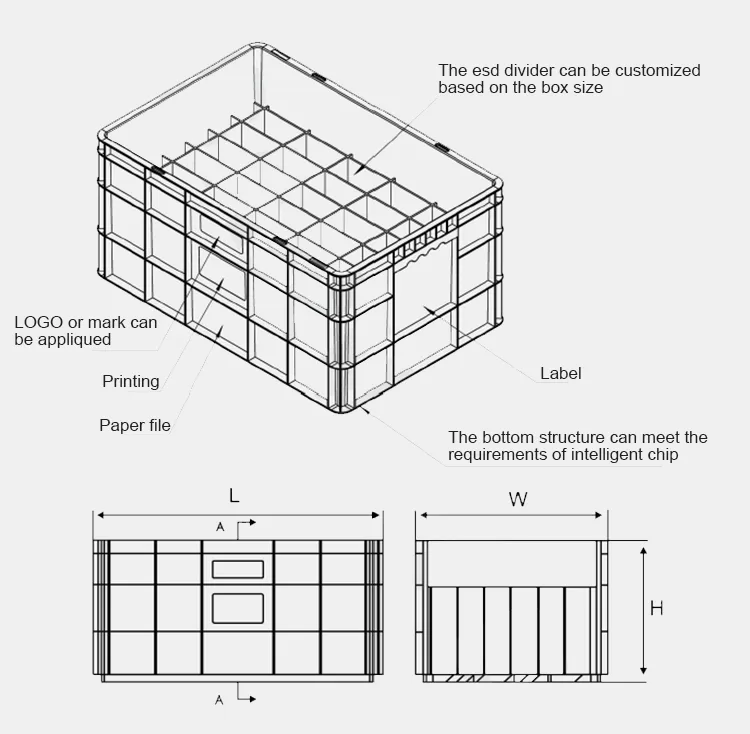

2. Can be customized according to user requirements of various specifications, sizes, with cover,dustproof, anti-static, beautiful appearance.

3. Anti-static circulation boxes are designed and made according to the size provided by customers, so as to achieve the most reasonable loading and multiple boxes can be overlapped.

4. Effectively utilizing the workshop space, increasing the storage of electronic components, PCB boards and dust-free workshop components, and saving production costs.

5.Polypropylene – resistant to most oils, acids and alkalis, noise absorbent on conveyors, withstands temperatures between -20° and +100° Celsius

continue reading