ESD (Electrostatic Discharge) bags, also known as anti-static bags or static shielding bags, are specialized packaging materials designed to protect sensitive electronic components from electrostatic damage. They are used in various industries, including electronics manufacturing, semiconductor, aerospace, and telecommunications.

ESD bags are constructed using materials that dissipate electrostatic charges, preventing static electricity from building up and damaging the contents. These bags typically have a multilayer structure consisting of:

- Outer Layer: The outer layer of an ESD bag is usually made of a static dissipative material, such as a metallized polyester film. This layer provides a barrier to external electrostatic charges and prevents charge transfer to the contents.

- Middle Layer: The middle layer is usually made of a conductive material, such as aluminum foil or carbon-loaded polyethylene. This layer helps to provide shielding against electrostatic fields and further dissipates any charges generated within the bag.

- Inner Layer: The inner layer, in direct contact with the contents, is typically made of a static dissipative polyethylene material. This layer helps to minimize triboelectric charging and prevents direct contact between sensitive components and the conductive middle layer.

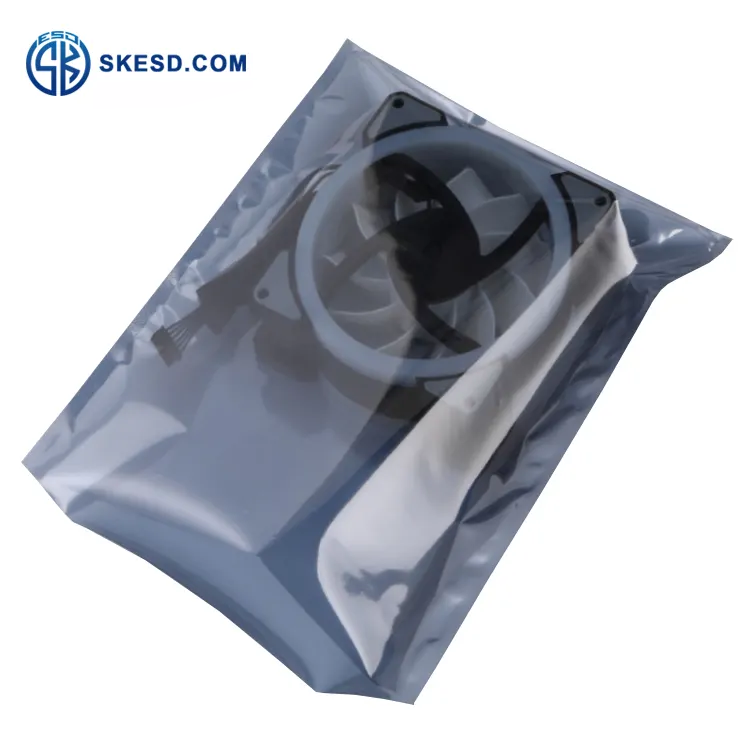

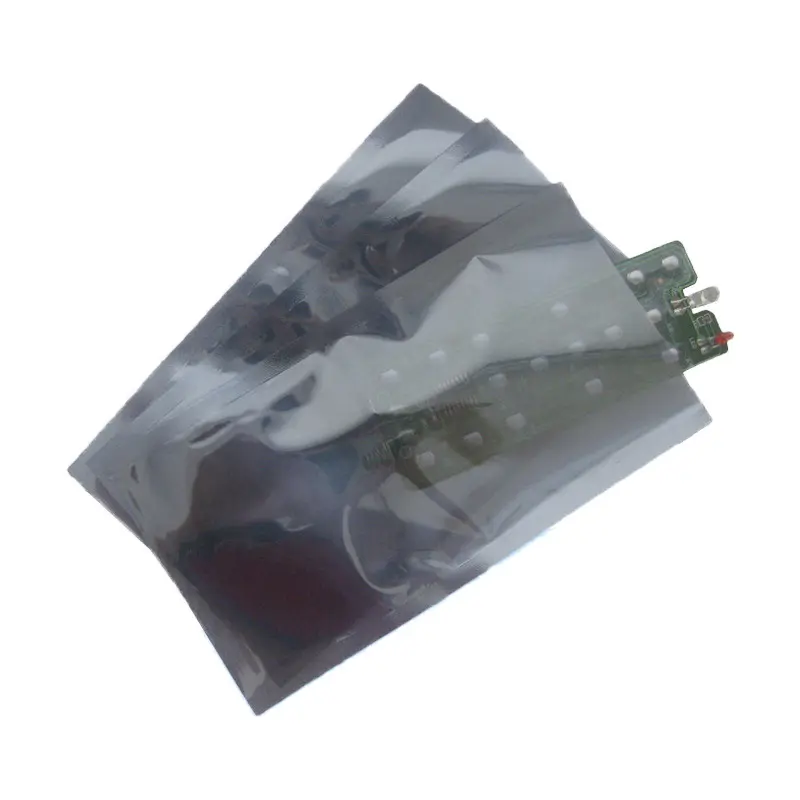

ESD bags are available in various sizes and formats, including open-top bags, ziplock bags, and heat-sealable bags. They are used to store and transport electrostatic-sensitive devices (ESDs), such as integrated circuits, printed circuit boards, and electronic components.

By using ESD bags, companies can protect sensitive electronics from electrostatic damage caused by electrostatic discharge (ESD) events. ESD can result from activities like handling, transportation, or contact with charged surfaces. ESD bags prevent the accumulation and transfer of electrostatic charges, ensuring the integrity and functionality of the enclosed components.

It’s important to note that ESD bags should be properly handled and used in conjunction with appropriate ESD control measures, such as esd mats, wrist straps, and ESD-safe workstations. These measures help to maintain a controlled electrostatic environment and minimize the risk of ESD-related failures.

The ESD shielding bag is a remarkable solution that provides […]

To safeguard your valuable electronics from ESD, it’s essential to […]

The Importance of ESD Bags in Safeguarding Electronics In today’s […]

We need understand the critical importance of ESD (Electrostatic Discharge) […]

In this comprehensive guide, we will delve into the intricacies […]