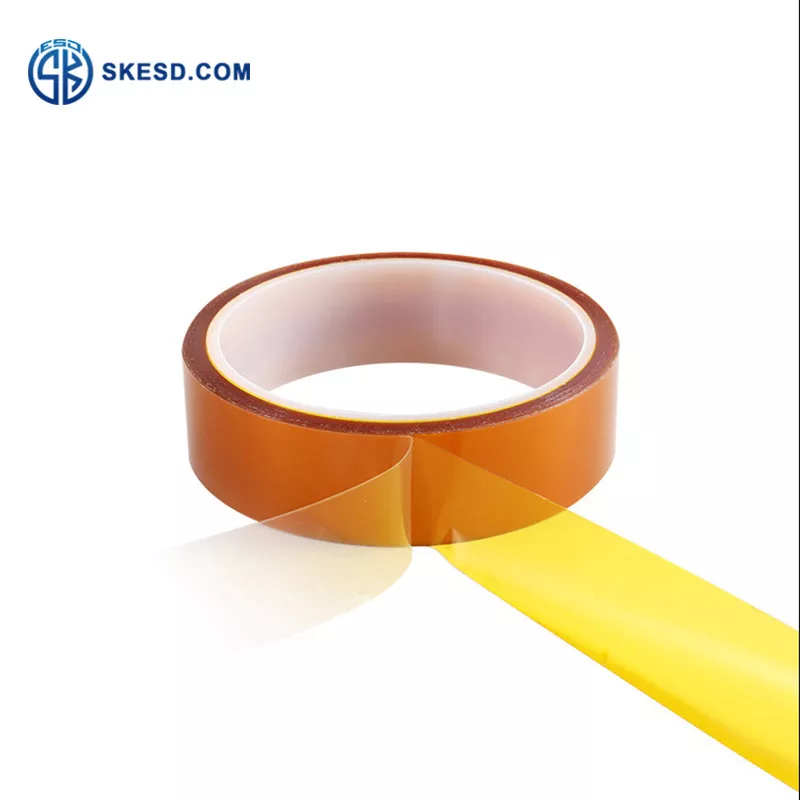

ESD tapes are specialized adhesive tapes designed to provide protection against electrostatic discharge. These tapes feature unique properties that allow them to dissipate static charges and prevent them from accumulating on sensitive components. These tapes are commonly used during the manufacturing, assembly, and transportation processes of electronic devices. They serve as a physical barrier, shielding sensitive components from potential damage caused by ESD events.

Features and Benefits of ESD Tape:

ESD tapes offer several features and benefits that make them a preferred choice for ESD protection. These include:

- Conductive or dissipative properties: These tapes are manufactured with conductive or dissipative materials, which allow them to quickly and effectively dissipate static charges.

- High adhesive strength: ESD tape adhere firmly to various surfaces, providing secure protection during handling and transportation.

- Customizable options: These tapes are available in various widths, lengths, and thicknesses to accommodate different application requirements.

- Easy application and removal: ESD tape can be easily applied and removed without leaving residue or causing damage to the surface.

- Durability: These tapes are designed to withstand harsh environmental conditions and provide long-lasting ESD protection.

Applications of ESD Tape:

ESD tapes find extensive use in various industries where ESD protection is critical. Some common applications include:

- Electronics manufacturing: These tapes are used during the production and assembly of electronic components, preventing ESD-related damage at every stage of the manufacturing process.

- Circuit board assembly: ESD tape help secure delicate circuit board components, reducing the risk of ESD damage during assembly, soldering, and rework processes.

- Packaging and shipping: These tapes are used to secure and protect electronic devices during transportation, ensuring they arrive at their destination in optimal condition.

- Cleanroom environments: These tapes are compatible with cleanroom protocols and are often used to protect sensitive electronic components in controlled manufacturing environments.

ESD tapes play a crucial role in safeguarding electronic devices […]

In the realm of electronics, the potential dangers of electrostatic […]