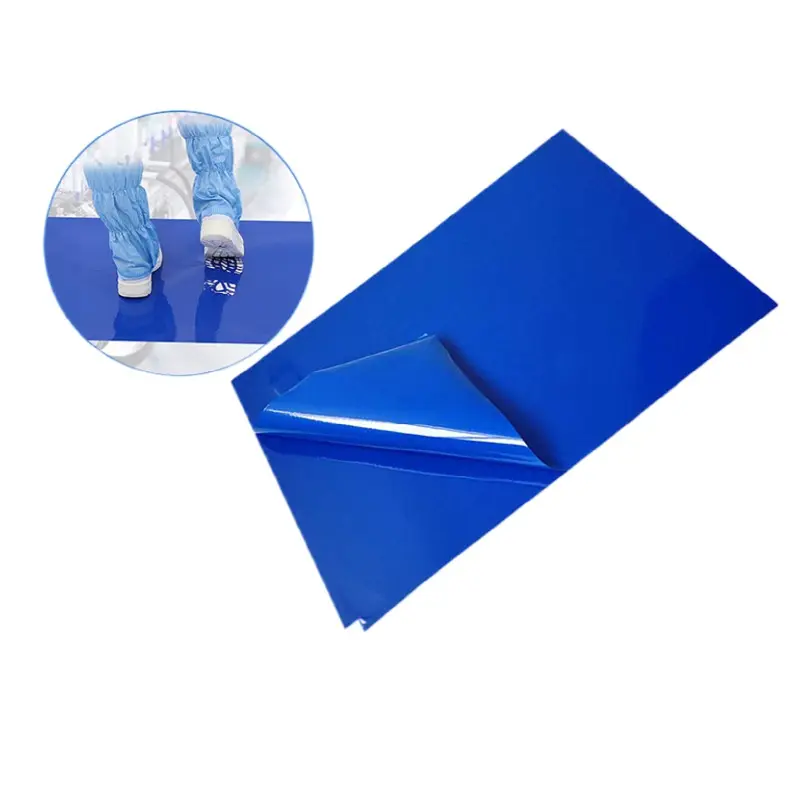

Sticky mat is a cleaning product commonly used in industries such as semiconductor, electronics, medical, and pharmaceutical to effectively prevent external dust, contaminants, and microorganisms from entering a clean work area. The working principle of sticky mats is to use a layer of special adhesive surface to remove dust and contaminants from the soles of shoes before personnel enter the clean area.

The steps for using sticky mats are as follows:

- Place the sticky mat at the entrance or transition area to the clean area.

- Ensure that the adhesive surface of the sticky mat is exposed to remove dust and contaminants from the soles of shoes.

- When personnel walk over the sticky mat, they should step back and forth on it to ensure the soles of their shoes are clean.

- When the adhesive surface becomes dirty or no longer effective, it should be replaced with a new sticky mat.

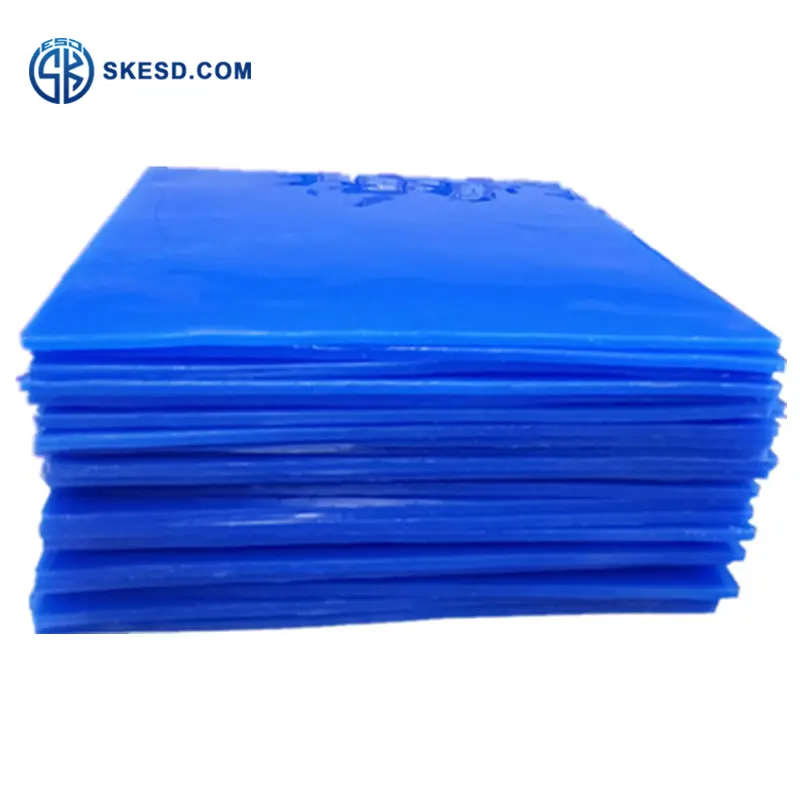

Sticky mats are typically made up of multiple layers of plastic film, with each layer’s surface covered with a layer of adhesive material. The stickiness of the material is typically adjusted by the manufacturer based on specific needs. When using sticky mats, the following should be noted:

- Do not place the sticky mat in wet or muddy areas to avoid contaminating or damaging the adhesive surface.

- Sticky mats need to be replaced regularly, with the frequency determined by usage and the working environment.

- When replacing sticky mats, the old sticky mats should be disposed of correctly to avoid contaminating the environment or causing health hazards.

- When using sticky mats, they should be used in conjunction with other cleaning supplies and hygiene control measures to ensure the cleanliness and hygiene of the work area.

Sticky mats are a simple yet effective hygiene control tool that can help protect the cleanliness and hygiene of the work area, reduce product contamination and damage, and improve work efficiency and quality.

In medical facility, laboratory, manufacturing plant, or even a home, […]

If a sticky mat is not used for a long […]

the wrinkle of the sticky mat can affect its use. […]

Both washable and disposable sticky mats have their own advantages […]