ESD Fabric dissipation principle is based on the discharge and neutralization of electric charge two mechanisms.

When grounded, the fabric on the Static electricity in addition to the conductive fiber corona discharge is neutralized, but also through the conductive fiber to the earth discharge; not grounded with the conductive fiber weak corona discharge and dissipate electricity.

Corona discharge principle

Local self-sustaining discharge of gas medium in homogeneous electric field is the most common form of gas discharge. It is in the vicinity of the tip electrode with a large radius of curvature, because the local electric field wetting exceeds the ionization field strength of the gas, causing the gas to ionize and excite, and thus the power discharge occurs. When corona occurs, a light can be seen around the electrode with a sizzling sound.

What is Anti-static clothing?

Anti-static clothing is a special kind of work clothes. Its special fabric special use, with efficient and permanent anti-static and dustproof performance. It is suitable for petroleum, chemical, electronic and other industries. However, there is more than one kind of anti-static clothing. Anti-static clothing manufacturers design anti-static clothing with different performance according to the needs of different industries. Different places and different sensitivities should choose different levels of anti-static work clothes.

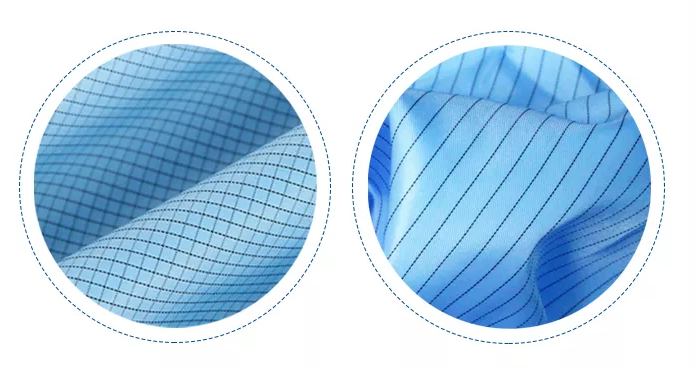

- Anti-static Conductive silkFabricSpecial polyester filament and high performance permanent conductive fiber woven by a special process, the way for the warp embedded woven or weft embedded conductive fiber.

It is mainly used for making dust proof clothes and anti-static work clothes with stripe type and grid type.

This kind of fabric made by special sewing process has excellent anti-static and dust proof performance, anti-static efficient and lasting. With the characteristics of soft, thin and smooth, and clear weaving pattern.

- Anti-static TC FabricThe main material is polyester and cotton, woven from polyester fiber, cotton blend, inlaid with conductive fiber. Fabric styles include plain, fine twill, coarse twill, etc.

The surface is brighter, smoother and stiffer to the touch, with a little elasticity. When external force is applied, the crease is not obvious and the crease recovery time is shorter than that of cotton fabric.

- Anti-static TR Fabric

The main material is Polyester + rayon, this type of blended fabric is characterized by smooth and clean fabric, bright colors, strong wool style, good elasticity, good moisture absorption, and poor iron resistance.

- Anti-static CVC FabricMade of cotton and polyester fiber blend, inlaid with conductive fiber weave.

The main component of CVC fabric is cotton. The cotton content should be above 65% to be called CVC, and the polyester content is called TC fabric when it is higher than the cotton content. Anti-static CVC fabric has good abrasion resistance and wrinkle resistance, soft and comfortable hand feel.

- Anti-static Cotton FabricCotton as raw material, through the textile process and conductive fiber interweaving, with moisture absorption, moisture, heat resistance, alkali resistance, and feel soft, comfortable and other characteristics.

Because the price of cotton itself is slightly more expensive, the price of this fabric will also be higher, but its excellent performance, but also other fabrics are incomparable.

Due to the special nature of anti-static work wear, not everyone can produce it at will. The country has a series of standards for the performance of anti-static clothing. The anti-static clothing produced by anti-static clothing manufacturers must undergo a series of tests. Only those that meet the national standards can be considered qualified anti-static clothing.

Due to the special nature of anti-static work wear, not everyone can produce it at will. The country has a series of standards for the performance of anti-static clothing. The anti-static clothing produced by anti-static clothing manufacturers must undergo a series of tests. Only those that meet the national standards can be considered qualified anti-static clothing.

How to extend the use of anti-static clothing?

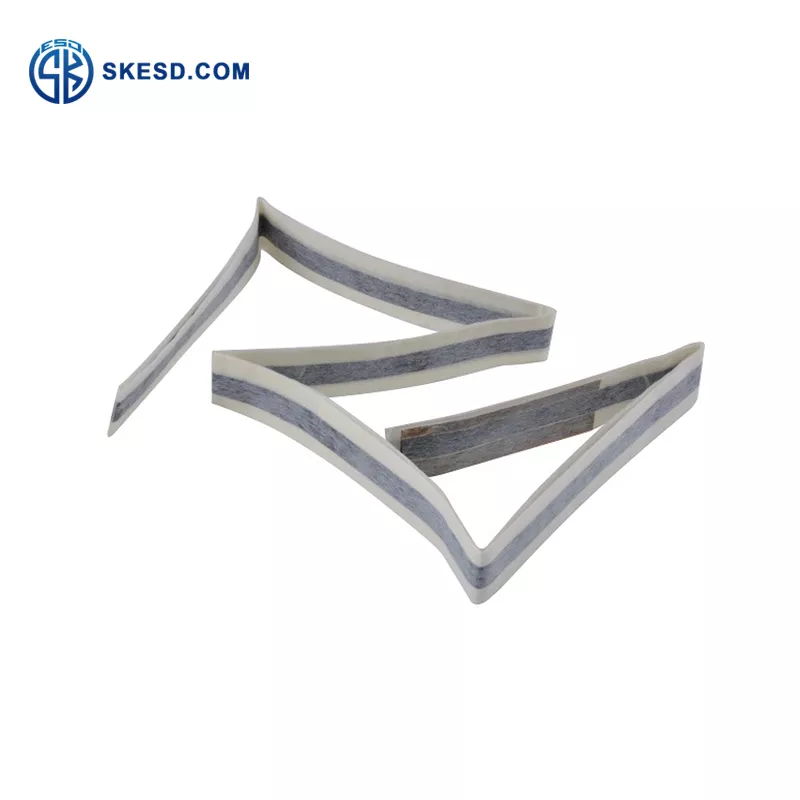

(1)Workmanship

Professional production technology is also the key to determine the service life of anti-static work clothes. For example, the car line is not neat, inlay clip processing is not appropriate, wear a period of time will be cracked or other parts of the damage, resulting in anti-static clothing service life shortened.

(2)Precautions for use

Before wearing anti-static clothing into the clean room, check whether there are prohibited items in the pockets, such as cigarettes, lighters, tissues, wallets, cell phones, etc. Four, washing.

(3)Method

Newly sewn anti-static clothing can be washed directly, but old or recycled clothes should be checked for damage, stains and other problems before washing. The use of strong acid and alkali detergent is prohibited, neutral detergent should be used, and try to operate in a place with less dust.

(4)Storage

During transportation, care should be taken to wear anti-static overalls, not to break the package, and to prevent sunlight exposure and high temperature; dragging by hand hook is strictly prohibited during transportation. Clothing should be stored in a dry and ventilated place to prevent mildew and deterioration. Storage is more than 200mm from the ground and wall, and more than 1m from all heat generating components. Should avoid direct sunlight, shall not be placed in the open air.

(5)Maintenance

Anti-static clothing is generally cleaned with neutral detergent, do not use strong acid and alkali detergent. When washing, please do not mix with other clothes. Use hand wash or washing machine gentle washing program to avoid fracture of conductive fibers. Washing water temperature should be below 40℃ and rinsing should be done with normal temperature water. Washing time should be as short as possible, but rinsing must be sufficient to remove residual detergent.

continue reading