We need understand the critical importance of ESD (Electrostatic Discharge) prevention when it comes to safeguarding sensitive electronic components. Whether you’re an electronics manufacturer, distributor, or simply an individual looking to protect your valuable gadgets, the use of anti-static bags is paramount. In this comprehensive guide, we will delve into the world of anti-static bags, exploring their purpose, benefits, and how they can effectively prevent ESD damage.

Understanding Electrostatic Discharge (ESD)

Before we delve into the specifics of antistatic bags, it is crucial to grasp the concept of Electrostatic Discharge (ESD). ESD refers to the sudden flow of electric current between two objects with different electric potentials. When this discharge occurs, it can cause irreversible damage to electronic components, leading to malfunctions, reduced lifespan, or even complete failure.

The Importance of ESD Prevention

In today’s technology-driven world, electronic components are becoming increasingly sensitive and delicate. Even the slightest ESD event can disrupt their functionality, resulting in substantial financial losses for businesses and personal inconvenience for individuals. As a result, implementing effective ESD prevention measures, such as utilizing anti-static bags, is crucial.

Introducing AntiStatic Bags

Anti-static bags, also known as ESD bags, are specially designed packaging materials that provide a protective shield against Electrostatic Discharge. These bags are constructed using multiple layers of polyethylene or polypropylene, with an additional anti-static coating to create a controlled environment that dissipates static charges. By utilizing these bags, you can effectively minimize the risk of ESD damage during storage, transport, and handling of electronic components.

Types of AntiStatic Bags

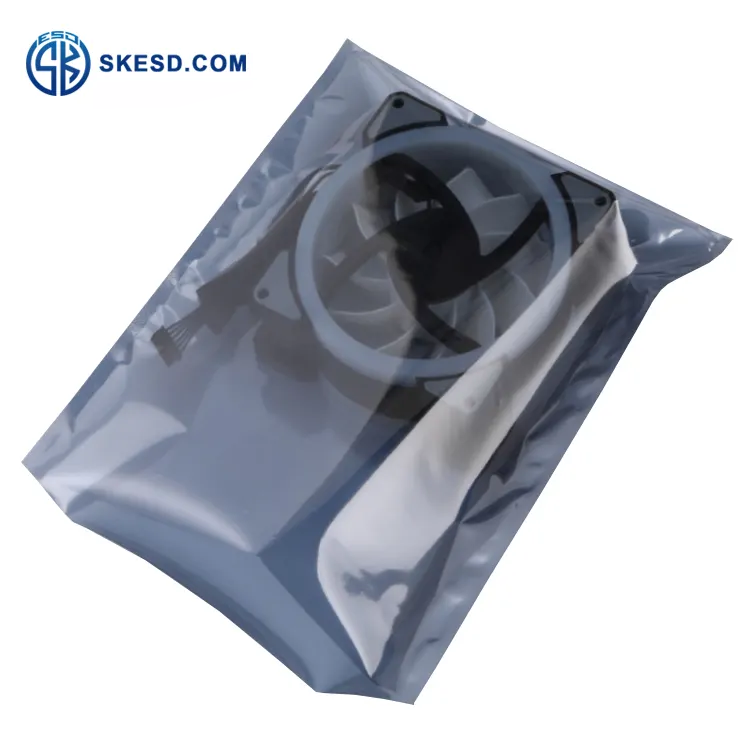

- Metalized Shielding Bags: Metalized shielding bags are constructed with a layer of metallic polyester film, providing excellent protection against ESD and external electromagnetic interference. These bags are commonly used when transporting or storing highly sensitive components that require a high level of ESD protection.

- Static Shielding Bags: Static shielding bags, often referred to as Faraday cage bags, are composed of a multilayer structure that includes a metalized layer, a conductive layer, and a dissipative layer. This combination creates a protective barrier that effectively blocks external electrostatic fields and prevents the buildup of static charges within the bag.

- Pink Anti-Static Bags: Pink anti-static bags are made from low-density polyethylene (LDPE) and are treated with an anti-static additive. These bags are suitable for protecting non-sensitive electronic components from static charges during storage and transport.

- Black Conductive Bags: Black conductive bags are primarily used when handling highly sensitive components that require the highest level of protection against static electricity. These bags are made from carbon-loaded polyethylene, which provides a conductive path for static charges to dissipate effectively.

Advantages of Anti-Static Bags

- ESD Protection: The primary advantage of utilizing anti-static bags is the effective ESD protection they offer. By creating a controlled environment that dissipates static charges, these bags ensure the safety and integrity of electronic components.

- Moisture Barrier: Many antistatic bags also incorporate moisture barrier properties, preventing moisture ingress that could potentially damage electronic components. This feature is especially crucial when components are stored or transported in humid environments.

- Transparency and Visibility: Most anti-static bags are transparent, allowing for easy identification and inspection of the contents without compromising ESD protection. This transparency enhances operational efficiency and reduces the risk of mishandling or misplacement.

- Durability and Reusability: Anti-static bags are designed to be durable, ensuring that they can withstand the rigors of handling, transportation, and storage. Furthermore, many types of anti-static bags can be reused, making them a cost-effective and environmentally friendly choice.

Best Practices for Anti-Static Bag Usage

To maximize the effectiveness of anti-static bags in preventing ESD damage, it is essential to follow some best practices:

- Proper Handling: Always handle anti-static bags with clean, dry hands to prevent any potential transfer of static charges. Additionally, avoid dragging or sliding bags against surfaces that can generate static electricity.

- Sealing and Closure: Ensure a proper seal or closure of the anti-static bags to maintain the controlled environment. Utilize methods such as heat sealing, zip-locking, or twist ties, depending on the bag type.

- Compatibility: Select the appropriate anti-static bag based on the sensitivity of the electronic component. Different components may require different levels of ESD protection, so it is crucial to choose the bag that meets the specific requirements.

- Storage and Transportation: Store and transport anti-static bags in a controlled environment with proper temperature and humidity conditions. Avoid exposing the bags to extreme temperatures, direct sunlight, or excessive moisture.

In conclusion, antistatic bags play a vital role in ESD prevention and protecting electronic components from potential damage. By choosing the right type of antistatic bag and following best practices for usage, you can significantly reduce the risk of ESD-related issues, ensuring the longevity and reliability of your electronic devices.

We offer a wide range of high-quality antistatic bags that meet industry standards and cater to various ESD protection requirements. Visit our website or contact us today to explore our extensive selection and safeguard your valuable electronic components.

continue reading