In this article, we delve into the world of Anti-static fabric and explore why it is an essential component in various industries. Whether you are a professional in the electronics sector or simply curious about this fascinating field, our comprehensive guide will provide you with valuable insights.

Understanding Anti-static fabric

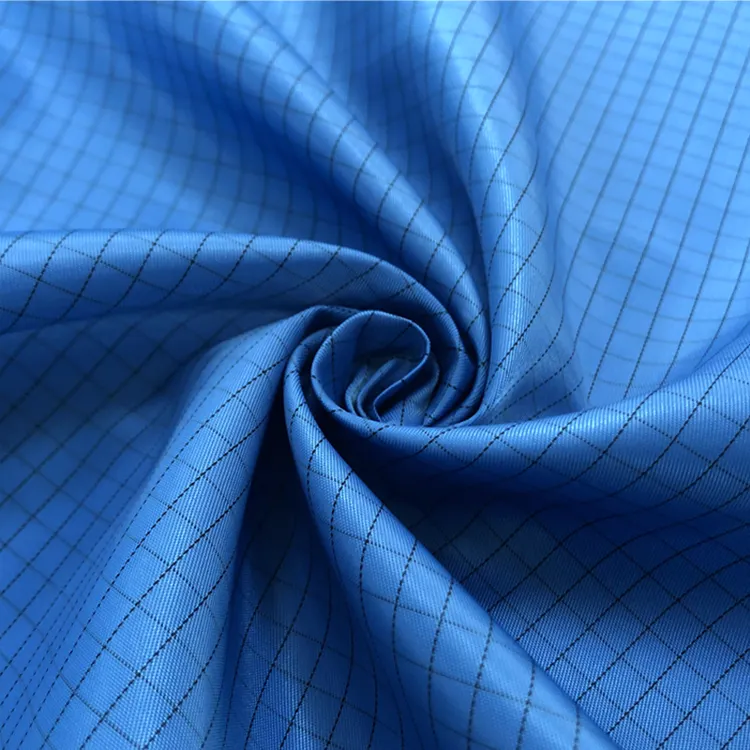

Anti-static fabric, or Electrostatic Discharge fabric, is a specialized material designed to dissipate or redirect static electricity. It is commonly used in industries where the presence of static electricity poses a significant risk to sensitive electronic components, such as semiconductor manufacturing, electronics assembly, and cleanroom environments. The fabric itself is made by incorporating conductive fibers, such as carbon or metal, into the textile structure, thereby creating a conductive path to discharge static charges.

Why Do You Need Anti-static fabric?

- Protection Against Electrostatic Discharge (ESD): The primary purpose of ESD fabric is to safeguard electronic components from damage caused by electrostatic discharge. When working with sensitive devices, even a small electrostatic discharge can lead to catastrophic failures, resulting in costly repairs and potential data loss. ESD fabric helps to dissipate and neutralize static charges, minimizing the risk of such incidents.

- Safety for Personnel: In addition to protecting electronic equipment, ESD fabric also plays a crucial role in ensuring the safety of personnel working in static-sensitive environments. By wearing garments made from ESD fabric, workers can prevent themselves from becoming a potential source of static electricity. This protects both the employees and the delicate electronic components they handle.

- Compliance with Industry Standards: Many industries, especially those involved in the manufacturing and handling of electronic devices, have strict guidelines and standards in place to prevent ESD-related issues. Employing ESD fabric is often a requirement to meet these standards and maintain the integrity of the products being produced.

- Preserving Product Quality: Electrostatic Discharge fabric helps maintain the quality and reliability of electronic components throughout their lifespan. By minimizing the risks associated with electrostatic discharge, the fabric ensures that the products remain in optimal condition, reducing the chances of premature failure or malfunction.

- Cost Savings: Investing in ESD fabric can lead to significant cost savings in the long run. By preventing damage to electronic devices and reducing the occurrence of failures, businesses can avoid costly repairs, replacements, and potential recalls. Moreover, maintaining a reputation for producing high-quality, reliable products can attract more customers and drive business growth.

Choosing the Right Anti-static fabric

When it comes to selecting the appropriate ESD fabric for your specific application, several factors should be considered:

- Conductive Properties: Different ESD fabrics possess varying levels of conductivity. It is important to assess the conductivity requirements of your industry and select a fabric that meets the specified standards. Conductivity can be measured in surface resistivity or surface resistance, both of which determine how effectively the fabric dissipates static charges.

- Durability and Longevity: The fabric’s durability is a crucial consideration, especially in industries where garments are subjected to frequent washing and wear. Look for fabrics that maintain their ESD properties even after extended use, ensuring consistent protection and performance.

- Comfort and Breathability: It is important to strike a balance between protection and comfort. The fabric should not impede the wearer’s mobility or cause discomfort during long working hours. Consider fabrics that offer breathability, moisture-wicking properties, and ergonomic designs for enhanced comfort.

- Compatibility with Other Safety Standards: Depending on the nature of your industry, there may be additional safety standards to adhere to, such as fire-resistant properties or chemical resistance. Ensure that the chosen the fabric aligns with these requirements to guarantee comprehensive protection for your workforce and products.

In conclusion, Anti-static fabric is an integral part of various industries where electrostatic discharge poses a threat to sensitive electronic components. By dissipating static charges and providing a safe working environment, Electrostatic Discharge fabric safeguards both personnel and products. Choosing the right Electrostatic Discharge fabric entails considering factors such as conductivity, durability, comfort, and compatibility with other safety standards.

continue reading