Modern industrial production attaches great importance to protection, especially in industries sensitive to electrostatic dust, such as microelectronics, electroscopic, solar energy, medicine, bioengineering, food, cosmetics, petrochemical industry, military industry, etc. The anti-static work clothes are made of polyester anti-static fabric through special process, and have efficient anti-static performance, which can effectively lead the accumulated electrostatic charge of human body to the ground, thus eliminating static electricity.

Anti static clothing plays a crucial role in various industries where electrostatic discharge (ESD) poses a risk. However, not all anti-static clothing is created equal.

Material Quality

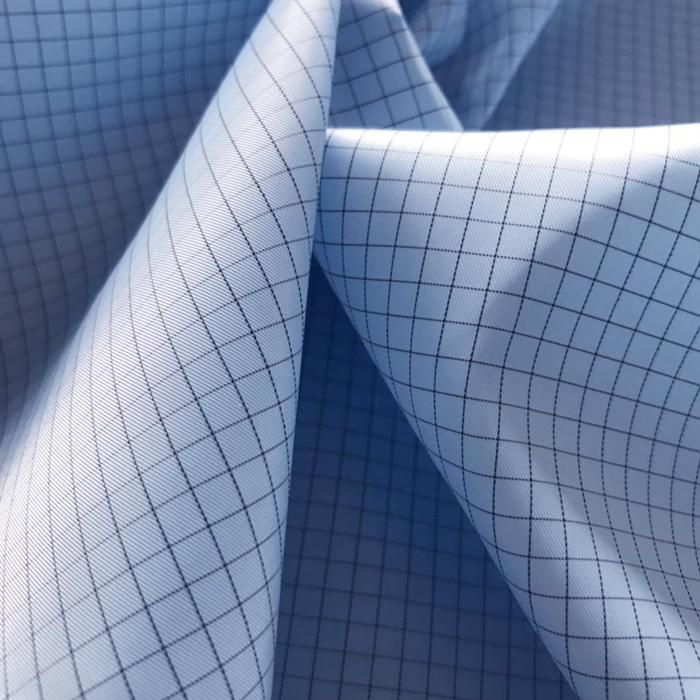

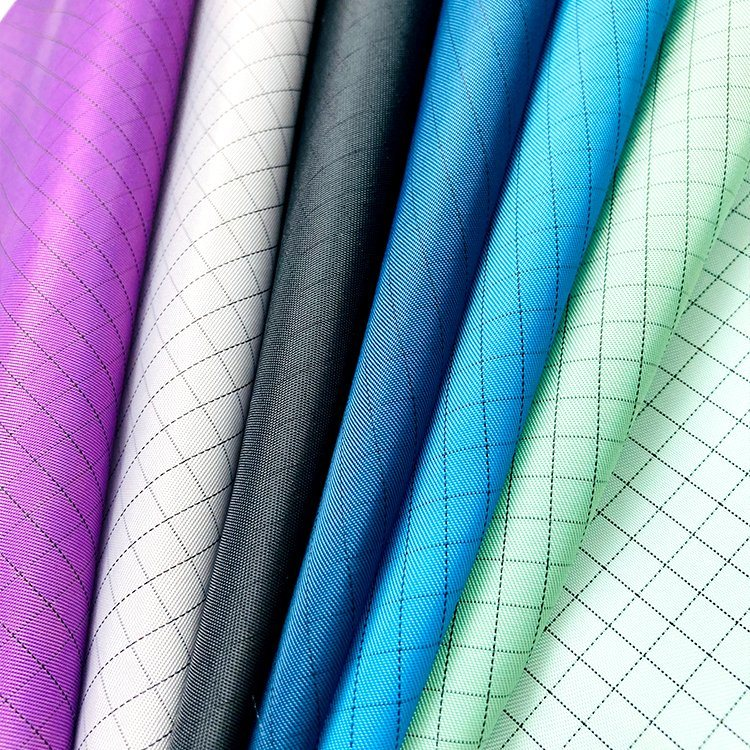

- High-Quality:Premium anti-static clothing is crafted from specialized fabrics, such as carbon fibers or a blend of synthetic fibers, that possess inherent anti-static properties. These materials effectively dissipate static charges, minimizing the risk of ESD.

- Poor-Quality:Inferior anti static clothing may employ low-grade materials that lack proper anti-static capabilities. They may wear out quickly, compromising their ability to neutralize static charges effectively.

Certification and Standards

- High-Quality:Reputable manufacturers adhere to recognized industry standards, such as ANSI/ESD S20.20 or IEC 61340-5-1, ensuring their anti-static clothing meets stringent requirements for ESD protection. They often provide certification labels or documentation to verify compliance.

- Poor-Quality:Substandard anti static clothing may lack proper certification or fail to meet recognized standards. Their effectiveness in preventing ESD incidents is questionable, potentially endangering the wearer and sensitive equipment.

Durability and Longevity

- High-Quality:Well-made anti static clothing is designed to withstand rigorous use and frequent laundering without compromising its anti-static properties. It maintains its effectiveness over an extended period, providing reliable protection.

- Poor-Quality:Cheaply made anti-static clothing may deteriorate quickly due to subpar stitching, weak fabric, or inadequate reinforcement. This compromises its durability, rendering it less effective in static control and necessitating frequent replacements.

Design and Comfort

- High-Quality:Leading manufacturers prioritize ergonomic designs and user comfort. They consider factors like breath ability, flexibility, and appropriate sizing, ensuring that anti-static clothing enables unhindered movement and minimizes discomfort during extended wear.

- Poor-Quality:Inferior anti-static clothing may exhibit poor design choices, leading to restricted movement, discomfort, and excessive heat retention. Ill-fitting garments can also impede proper grounding, negating their anti-static functionality.

Static Discharge Control

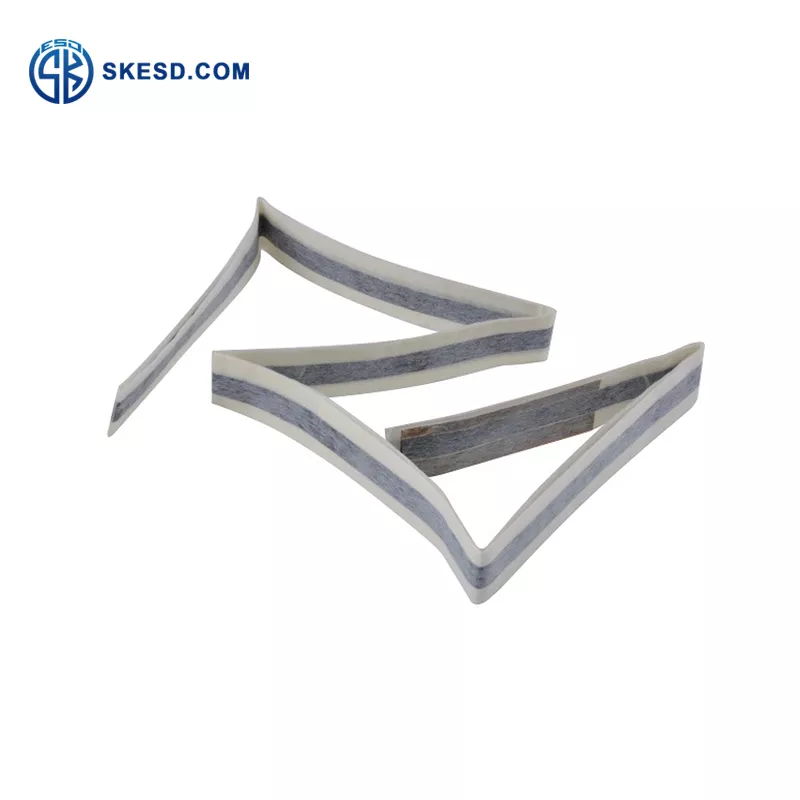

- High-Quality:Premium anti-static clothing incorporates various control measures, such as integrated grounding systems, conductive threads, or metal snaps. These features facilitate effective grounding and minimize the accumulation and transfer of static charges.

- Poor-Quality:Subpar anti-static clothing may lack adequate grounding mechanisms, relying solely on the fabric’s anti-static properties. This can result in inefficient static control and increased susceptibility to ESD incidents.

Investing in high-quality anti-static clothing is essential to ensure effective protection against electrostatic discharge. Superior materials, adherence to industry standards, durability, thoughtful design, and proper static discharge control are all crucial differentiators between high-quality and poor-quality anti-static clothing. By choosing reliable and certified products, individuals and industries can mitigate the risks associated with ESD, safeguarding both personnel and sensitive equipment.

continue reading