ESD (Electrostatic Discharge) fabric is a special type of fabric that is designed to dissipate or prevent electrostatic charges from building up on a surface.

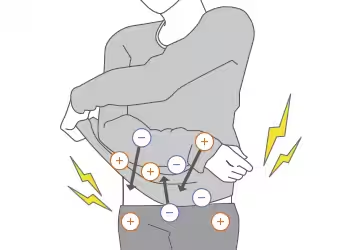

The generation of static electricity.

Static electricity on the human body is mainly caused by friction between clothing or clothing and the human body, the human body activities, between the skin and clothing and clothing and clothing friction between each other, it will generate static electricity. With the increase in household appliances and winter people wear more chemical fiber clothing, household appliances generated by the electrostatic charge will be absorbed by the body and accumulate, coupled with indoor walls and floors are mostly insulators, dry air, so more susceptible to electrostatic interference.

The hazards of static electricity.

Static electricity on the human body is also a certain danger, the human body generated by electrostatic interference can change the normal potential difference between the human body surface, affecting the normal electrophysiological process of the heart muscle and the normal conduction of electricity in the heart without interference. This static electricity can aggravate the patient’s condition or induce premature contractions, etc. The persistent static electricity will also raise the alkalinity of the blood, resulting in a decrease in the calcium content of the serum, increased calcium excretion, thus causing skin itching, hyperpigmentation, affecting the physiological balance of the human organism, interfering with human emotions, etc. It is caused by the electrostatic force generated by the computer screen attracting a large amount of suspended dust, which makes the face irritated.

What is ESD Fabric?

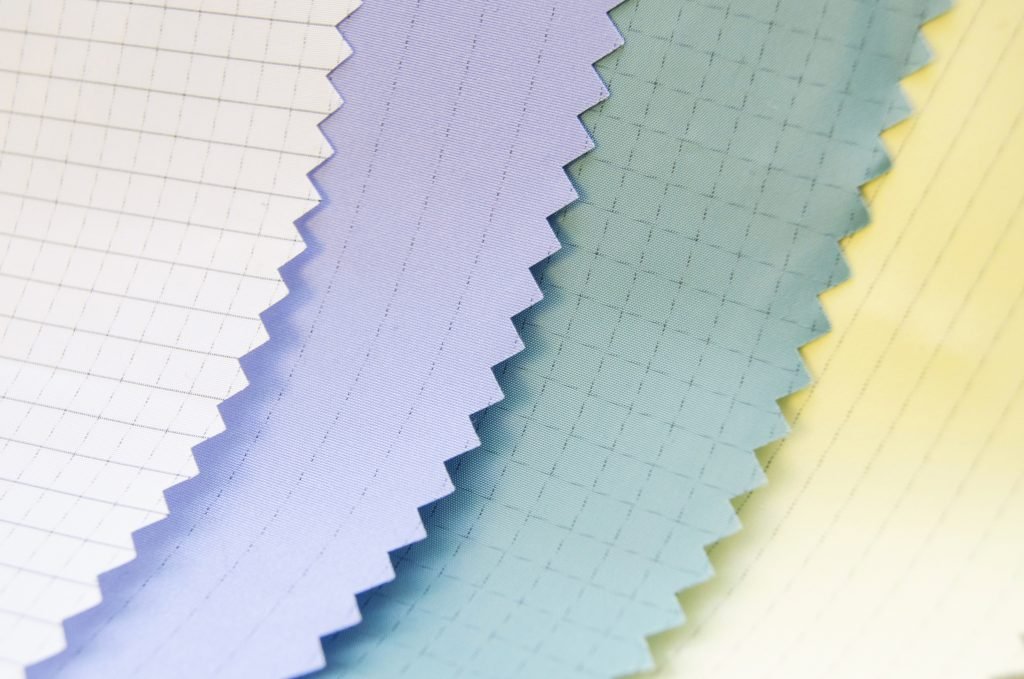

Using polyester as the main body, special polyester filament and high-performance permanent conductive fibers woven by a special process, warp embedded weave or warp and weft embedded weave conductive fibers. Used to make dustproof clothing, anti-static clothing, etc., used in medical, pharmaceutical, food, precision instruments, aerospace and other industries that are more sensitive to static electricity and high requirements for cleanliness.

ESD Fabric processing method.

- Fabric finishing with antistatic finishing agent

- Fiber grafting for the purpose of improving the moisture absorption of the fabric Blending and interweaving of sexed, hydrophilic fibers

- Blended or embedded woven conductive fibers

Features of ESD Fabric.

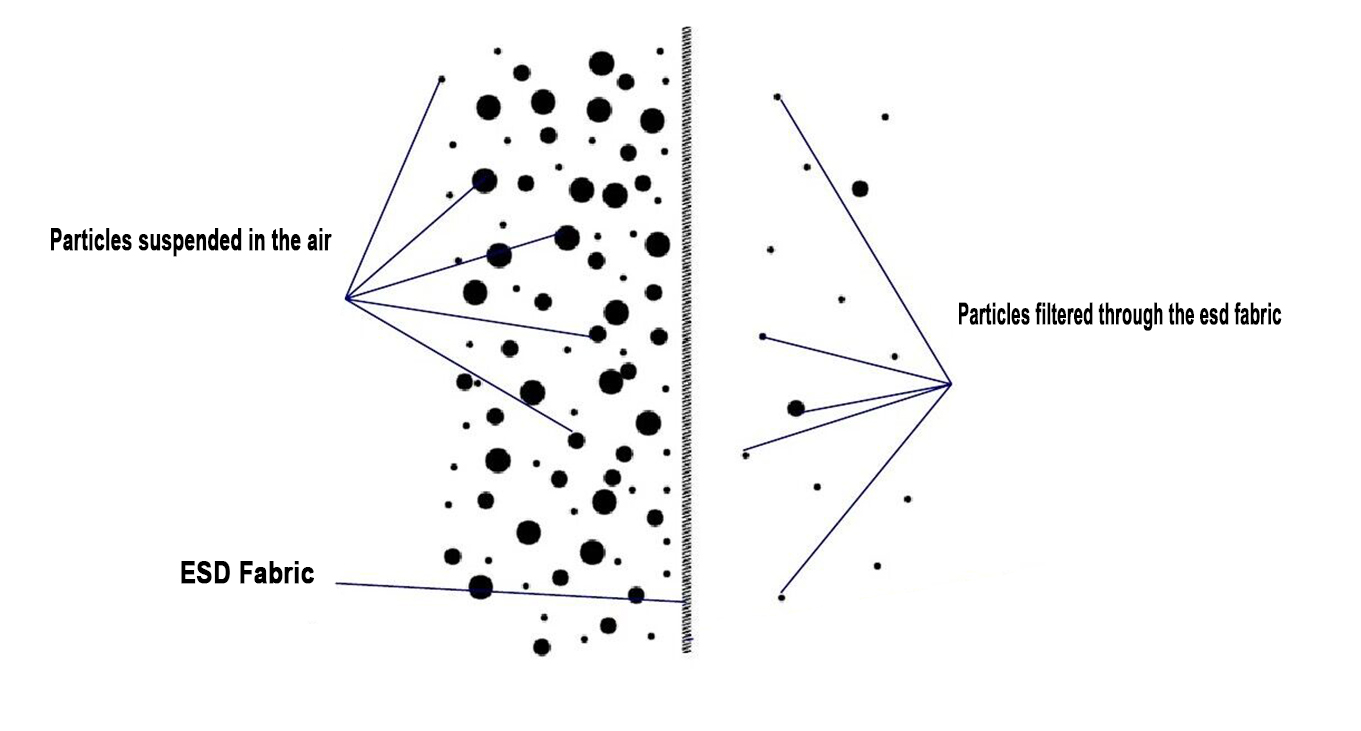

1.Anti-static function(Static electricity attracts dust)

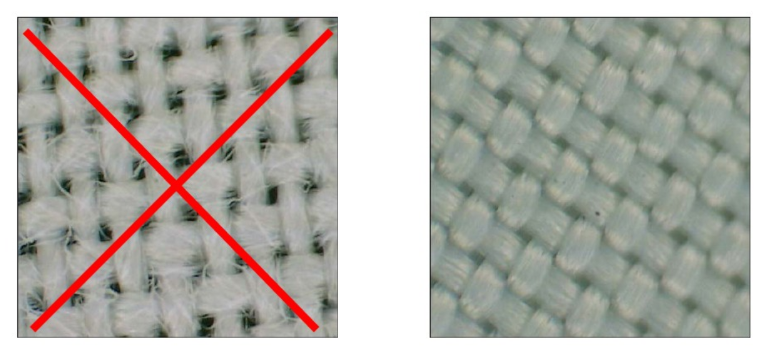

2.The fabric itself is not dusty

Thin Cotton Fabric Pure Polyester Fabric

3.The fabric should have good dust filtering properties

Four elements of ESD Fabric.

(1) Yarn

D:means the gram weight of 9000 meters of fiber

F:means how many strands of monofilament fiber a filament is made up of

100D/36F:A “bundle” of 36 monofilaments with a gram weight of 100D

How to choose yarn?

Large value of F: good filling effect, high dust filtration rate; high dust generation

Small value of F: small dust generation; large pore space between fibers, low dust filtration rate

According to the requirements of different levels of clean rooms, different choices of yarn thickness, arrangement density and F value of fibers should be made.

(2) Warp and weft density

The warp and weft density refers to the number of warp and weft threads arranged in a unit length.

The higher the cleanliness, the higher the warp and weft density of the selected fabric should be

Due to the objective conditions of different weaving machines, the warp and weft density can not be increased at will.

(3) Fabric organization

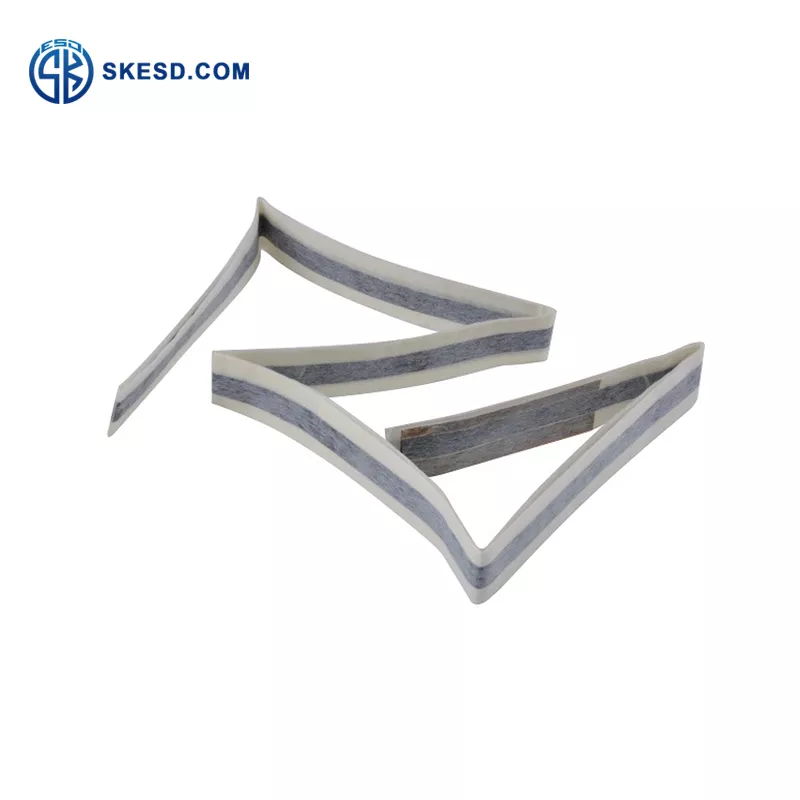

(4) Conductive fiber

Types of ESD fabric.

- Anti-static Conductive silkFabric

- Anti-static TC Fabric.

- Anti-static TR Fabric

- Anti-static CVC Fabric

- Anti-static Cotton Fabric

Selection instructions: Different types of fabrics are suitable for different anti-static requirements or clean environment

Application of ESD Fabric.

It can be made into anti-static clothing, anti-static masks, anti-static gloves, anti-static shoes or sets, etc. Application medical, pharmaceutical, food, precision instruments, aerospace and other industries that are sensitive to static electricity and have high requirements for cleanliness

continue reading