In industries where electrostatic discharge (ESD) poses a significant risk, the importance of reliable Anti-Static Attire cannot be overstated. Unfortunately, the market is flooded with poor-quality options that claim to provide adequate protection but fall short in various aspects.

Ineffective Static Dissipation

One of the primary dangers of poor-quality anti-static clothing is its inability to effectively dissipate static charges. Inferior materials or construction may result in weak or non-existent anti-static properties, leaving the wearer vulnerable to ESD incidents. This compromises worker safety and increases the risk of damage to sensitive equipment.

Lack of Certification

Reputable anti-static clothing manufacturers adhere to recognized industry standards and obtain certification to validate the efficacy of their products. However, poor-quality alternatives often lack proper certification, making it difficult to assess their reliability and compliance with essential safety regulations. Relying on uncertified anti-static clothing exposes individuals and organizations to unnecessary risks.

Limited Durability

Substandard anti-static clothing is often made from low-quality materials and lacks proper construction techniques, leading to reduced durability. Such garments may wear out quickly, compromising their anti-static functionality. Frequent replacements not only increase costs but also disrupt operations and may result in the use of inadequate alternatives during the replacement process.

Uncomfortable and Ill-Fitting Designs

Comfort and proper fit are crucial aspects of anti-static clothing. However, poor-quality options often prioritize cost-cutting over ergonomic design. Ill-fitting garments restrict movement and cause discomfort during extended use, impacting productivity and overall well-being. Additionally, inadequate ventilation and breathability can lead to excessive heat retention, further compromising user comfort.

Inadequate Grounding Mechanisms

Effective grounding is essential for anti-static clothing to function properly. Poor-quality options may lack proper grounding mechanisms, rendering them less effective in neutralizing static charges. This can result in the accumulation and transfer of static electricity, leading to potential ESD incidents and associated risks.

Inadequate Grounding Mechanisms

Effective grounding is essential for anti-static clothing to function properly. Poor-quality options may lack proper grounding mechanisms, rendering them less effective in neutralizing static charges. This can result in the accumulation and transfer of static electricity, leading to potential ESD incidents and associated risks.

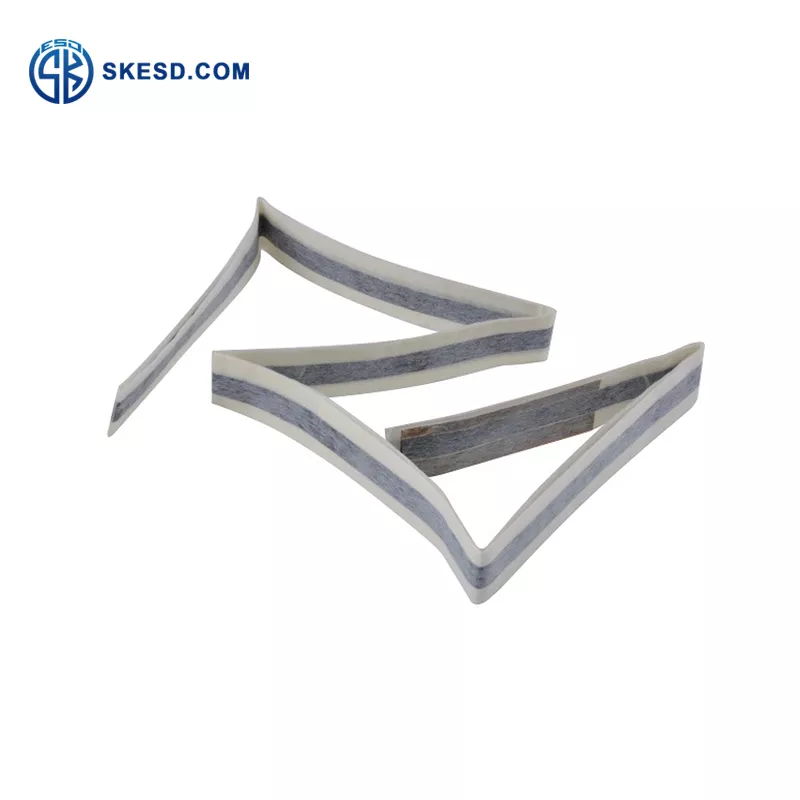

Potential Contamination

Some low-quality anti-static clothing may shed fibers or particles that can contaminate sensitive environments or equipment. Contamination can impair the performance of electronic devices, affect product quality, or even lead to safety hazards. The use of substandard garments thus introduces an additional risk that high-quality anti-static clothing aims to mitigate.

Choosing poor-quality Anti-Static Attire exposes individuals and organizations to significant risks, compromising worker safety, equipment protection, and overall productivity. Ineffective static dissipation, lack of certification, limited durability, uncomfortable designs, inadequate grounding mechanisms, and potential contamination are just some of the traps associated with substandard options. Investing in high-quality, certified anti-static clothing from reputable manufacturers is vital to ensure optimal protection, minimize risks, and uphold safety standards in ESD – prone environments.

continue reading