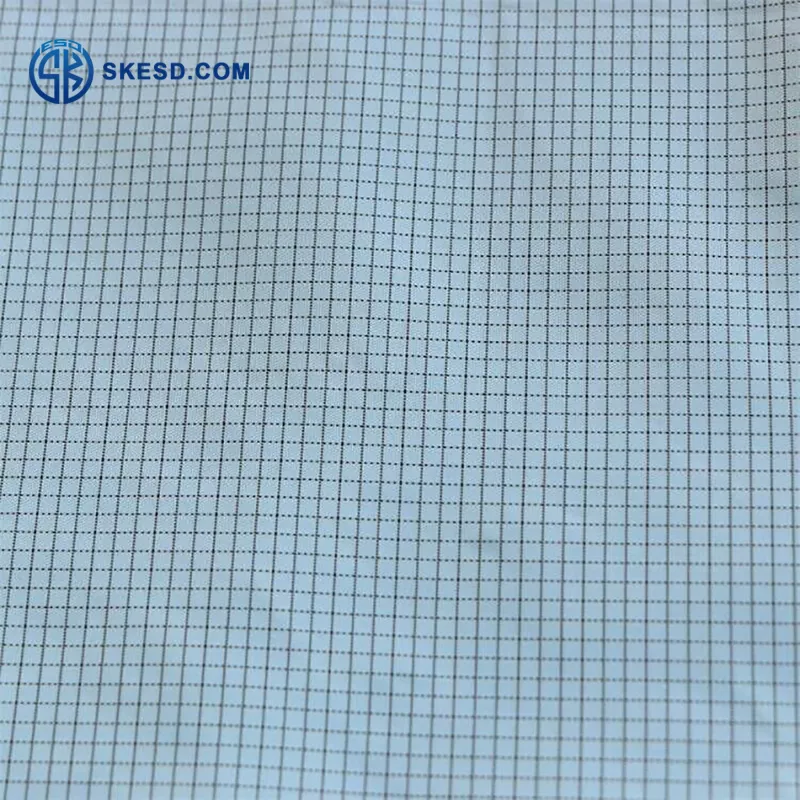

ESD polyester fabric is a specialized material that is designed to protect against electrostatic discharge, which can be a serious problem in manufacturing environments. This fabric offers a range of benefits, including durability, ease of use, and excellent static control properties. In this article, we’ll take a closer look at ESD polyester fabric and explore its many advantages.

Protection Against Electrostatic Discharge.

One of the primary benefits of using polyester fabric in manufacturing is its ability to protect against electrostatic discharge. This is particularly important in industries where sensitive electronic components are being produced or handled. ESD can cause damage to these components, leading to costly repairs and delays in production. ESD polyester fabric helps to prevent this by providing a barrier that dissipates static electricity and prevents it from building up on surfaces. This can help to ensure that products are manufactured to the highest quality standards and that production runs smoothly without interruptions.

Durability and Longevity.

In addition to its ability to protect against electrostatic discharge, Polyester fabric is also known for its durability and longevity. This fabric is designed to withstand the wear and tear of daily use in a manufacturing environment, making it a cost-effective choice for companies looking to reduce their maintenance and replacement costs. ESD polyester fabric is also resistant to chemicals and other substances commonly found in manufacturing settings, further enhancing its durability and longevity. Overall, using Polyester fabric can help companies to improve their production processes, reduce costs, and ensure that their products meet the highest quality standards.

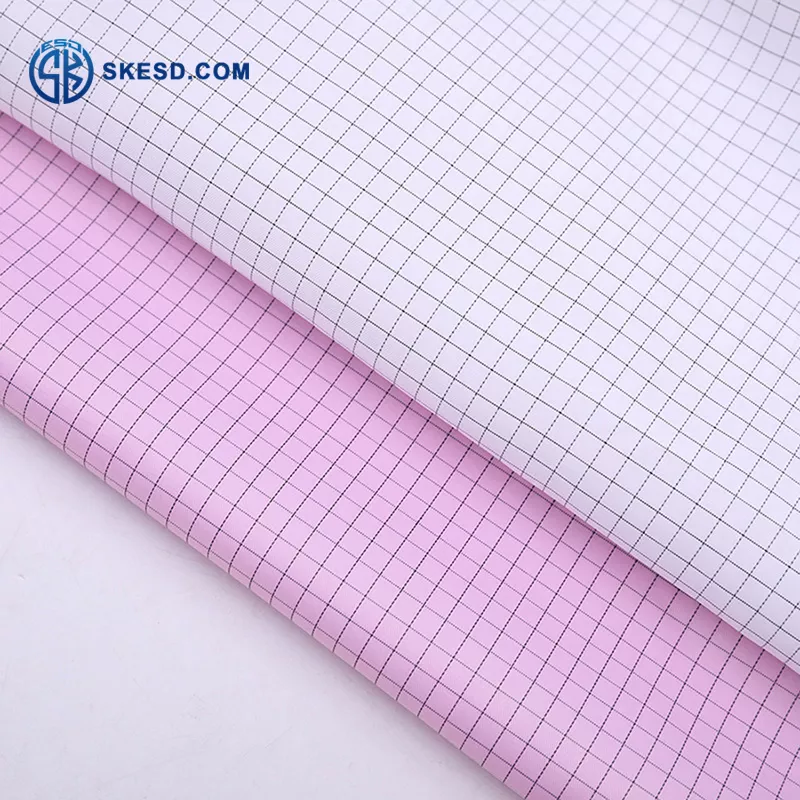

Versatility in Manufacturing Applications.

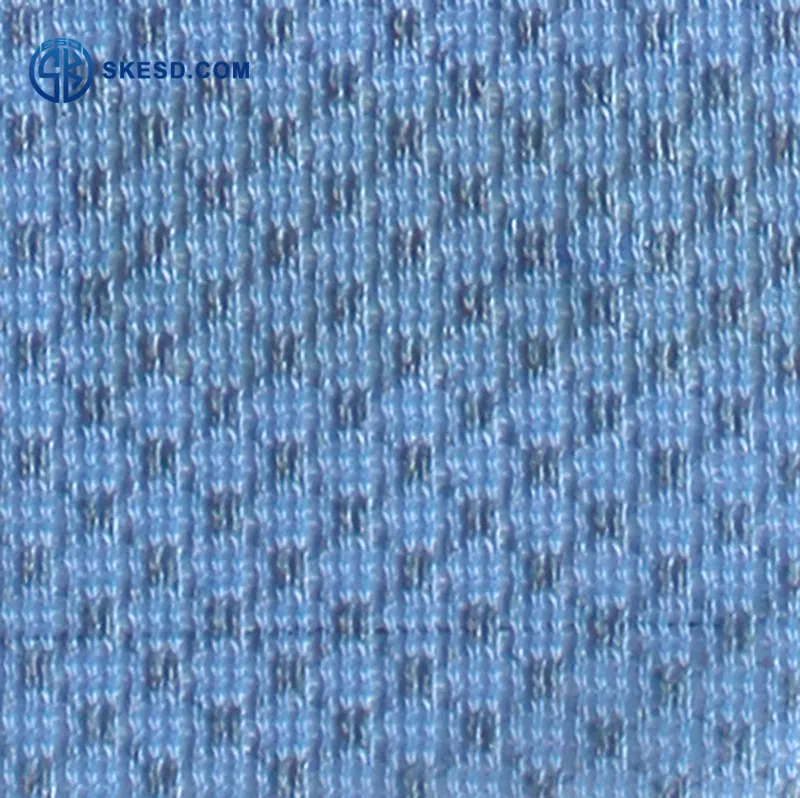

ESD fabric is a versatile material that can be used in a wide range of manufacturing applications. It is commonly used in the production of electronic components, such as circuit boards and semiconductors, where electrostatic discharge can cause serious damage. However, it can also be used in other industries, such as automotive manufacturing, where it can protect against static electricity and other hazards. Its versatility makes it a popular choice for companies looking for a reliable and cost-effective solution to their manufacturing needs.

Cost-Effective Solution.

One of the biggest benefits of using ESD polyester fabric in manufacturing is its cost-effectiveness. Compared to other materials that offer similar protection against electrostatic discharge, ESD polyester fabric is relatively inexpensive. This makes it an attractive option for companies looking to reduce their manufacturing costs without sacrificing quality or safety. Additionally, Polyester fabric is durable and long-lasting, which means that it can be used repeatedly without needing to be replaced frequently, further reducing costs over time.

Environmentally Friendly Option.

Another benefit of using ESD polyester fabric in manufacturing is that it is an environmentally friendly option. Unlike some other materials that may release harmful chemicals or pollutants during production or disposal, ESD polyester fabric is made from recycled materials and can be recycled again at the end of its lifespan. This makes it a sustainable choice for companies looking to reduce their environmental impact and promote sustainability in their operations.

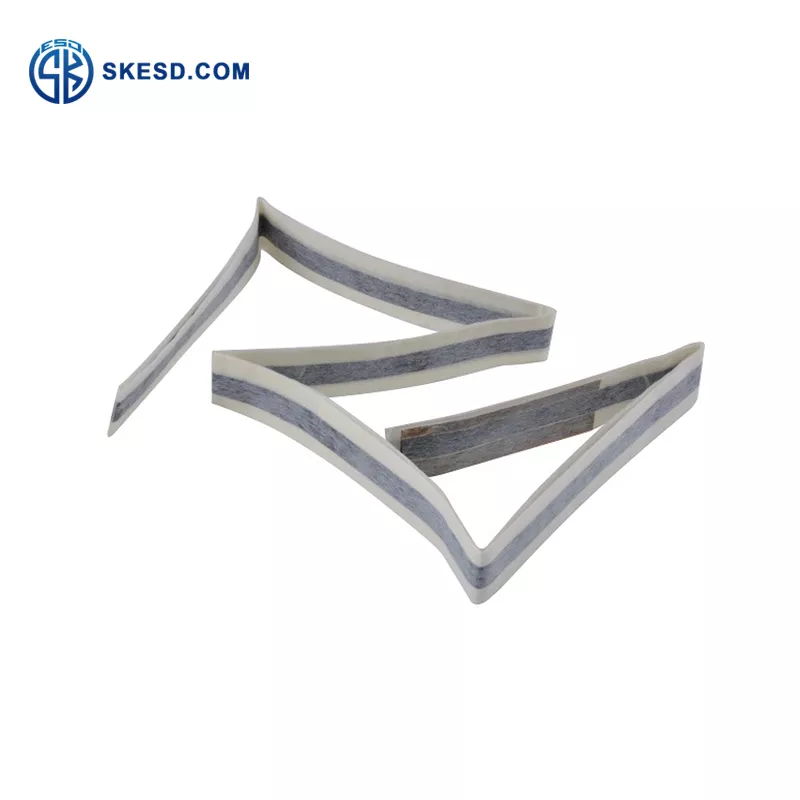

Related Products:

continue reading