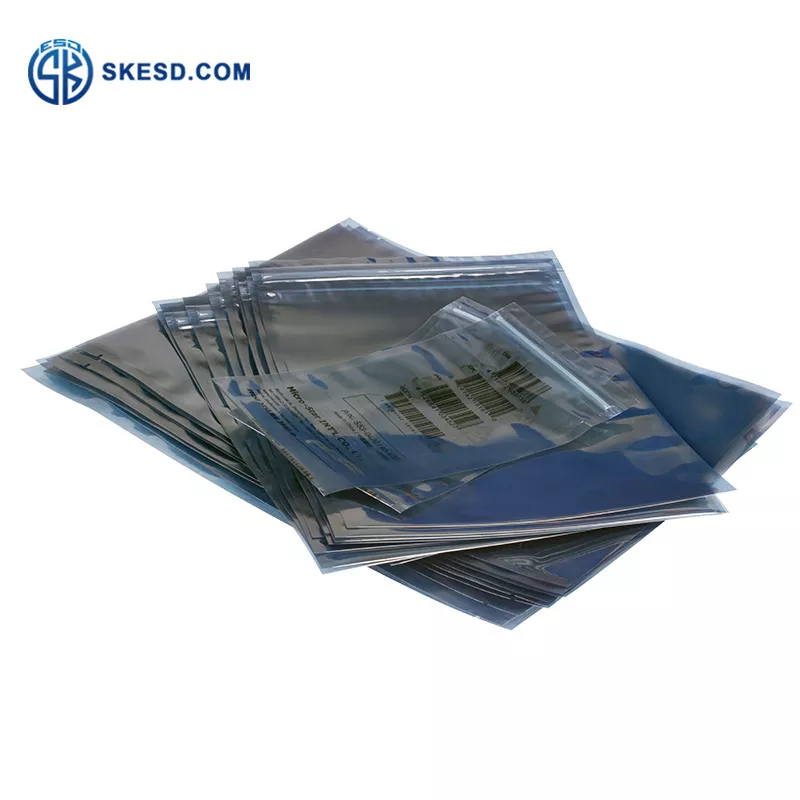

What Is an ESD Moisture Barrier Bag?

An ESD moisture barrier bag, also known as an ESD moisture barrier pouch, is a specialized packaging bag designed to protect electronic components from both electrostatic discharge and moisture. It is constructed with multiple layers of materials that provide a barrier against moisture ingress while offering electrostatic discharge protection.

How Does an ESD Moisture Barrier Bag Work?

ESD moisture barrier bags work on the principle of creating a controlled environment for the electronic components. These bags are made from materials with low moisture vapor transmission rates (MVTR) to prevent moisture from penetrating the bag. Additionally, they incorporate static dissipative properties to prevent electrostatic charges from accumulating on the bag’s surface and damaging the enclosed components.

Benefits of Using ESD Moisture Barrier Bags

Using ESD moisture barrier bags offers several benefits, including:

- Electrostatic Discharge Protection: ESD moisture barrier bags provide a protective shield against electrostatic discharge, preventing damage to sensitive electronic components.

- Moisture Protection: The moisture barrier properties of these bags safeguard electronic components from the harmful effects of humidity, moisture, and water exposure.

- Extended Shelf Life: By minimizing moisture and ESD-related damage, ESD moisture barrier bags help preserve the quality and functionality of electronic components during storage and transportation.

- Compatibility with Cleanroom Environments: ESD moisture barrier bags are available in cleanroom-compatible versions, ensuring their suitability for use in controlled environments.

Choosing the Right ESD Moisture Barrier Bag

When selecting an ESD moisture barrier bag, consider the following factors:

- Moisture Barrier Performance: Choose a bag with a low moisture vapor transmission rate (MVTR) to provide optimal protection against moisture ingress.

- ESD Protection Level: Ensure that the bag meets relevant ESD protection standards, such as ANSI/ESD S20.20, to effectively prevent electrostatic discharge.

- Size and Capacity: Select a bag size that accommodates the dimensions of the electronic components and provides sufficient space for proper sealing.

- Durability: Look for bags made from durable materials to withstand handling, transportation, and storage conditions without compromising their protective properties.

Proper Usage and Handling

To maximize the effectiveness of ESD moisture barrier bags, adhere to the following usage and handling guidelines:

- Preparation: Ensure the work area is clean and free from excessive humidity before handling the bags.

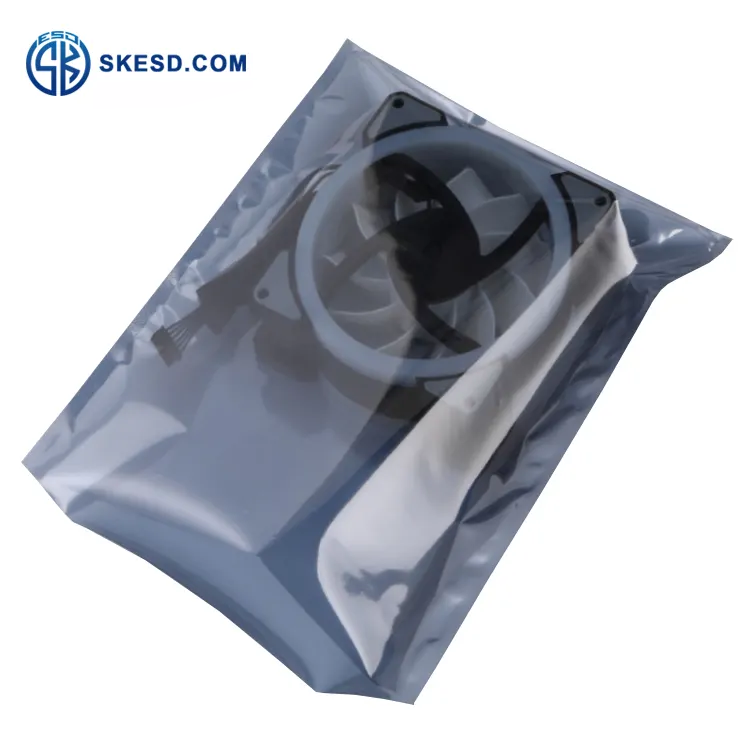

- Component Packaging: Place the electronic components in the bags, ensuring they are properly positioned and sealed.

- Sealing: Use an appropriate sealing method, such as heat sealing or zip-lock sealing, to create an airtight seal and maintain the bag’s moisture barrier properties.

- Labeling: Clearly label the bags with relevant information, including part numbers, lot codes, and handling instructions, for easy identification and traceability.

In Different Industries

ESD moisture barrier bags find applications in various industries where ESD and moisture protection are critical. Some industries that commonly utilize ESD moisture barrier bags include:

- Electronics manufacturing

- Semiconductor fabrication

- Aerospace and defense

- Medical device manufacturing

- Automotive electronics

- Telecommunications

Compliance Standards

ESD moisture barrier bags are subject to compliance standards to ensure their effectiveness and reliability. Some widely recognized standards include:

- ANSI/ESD S541: This standard provides guidelines for ESD control packaging, including moisture barrier requirements.

- J-STD-033: This standard outlines the handling, packaging, shipping, and use of moisture-sensitive components to prevent moisture-related failures.

Common Misconceptions

There are a few misconceptions surrounding ESD moisture barrier bags. Let’s address some of the common ones:

Misconception 1: ESD moisture barrier bags can completely eliminate moisture-related issues.

Misconception 2: Ordinary plastic bags offer similar protection as ESD moisture barrier bags.

Misconception 3: ESD moisture barrier bags are only necessary for long-term storage.

It is important to note that while ESD moisture barrier bags provide significant protection, they are part of a comprehensive ESD control and moisture prevention strategy.

ESD Moisture Barrier Bags vs. Other ESD Packaging Solutions

ESD moisture barrier bags are just one of the many ESD packaging solutions available. Here’s a comparison of ESD moisture barrier bags with other commonly used ESD packaging solutions:

- ESD Moisture Barrier Bags vs. ESD Shielding Bags: ESD shielding bags provide protection against electrostatic discharge but do not offer the same level of moisture barrier properties as ESD moisture barrier bags.

- ESD Moisture Barrier Bags vs. ESD Tubes: ESD tubes are primarily used for storing and shipping individual electronic components, while moisture barrier bags can accommodate multiple components and offer better moisture protection.

- ESD Moisture Barrier Bags vs. ESD Bins: ESD bins are designed for storing and transporting larger electronic assemblies and equipment, whereas moisture barrier bags are ideal for individual components and smaller items requiring moisture protection.

Future Developments in ESD Moisture Barrier Bags

As technology evolves, the development of ESD moisture barrier bags continues to advance. Some future developments in this field may include:

- Improved Materials: Advancements in material science may lead to the development of more effective and environmentally friendly moisture barrier films.

- Smart Packaging: Integration of smart features, such as humidity indicators or moisture-absorbing technology, to provide real-time feedback on the moisture levels inside the bag.

- Biodegradable Options: The industry may explore the use of biodegradable materials for ESD moisture barrier bags to address environmental concerns.

Conclusion

ESD moisture barrier bags play a vital role in protecting electronic components from the damaging effects of both electrostatic discharge and moisture. By creating a controlled environment, these bags ensure the longevity and functionality of sensitive electronic devices during storage and transportation. It is crucial to select the right bag, follow proper usage guidelines, and comply with industry standards to achieve optimal protection.

FAQs (Frequently Asked Questions)

1. Can ESD moisture barrier bags be reused? ESD moisture barrier bags can be reused if they are in good condition and retain their moisture barrier and ESD protection properties. However, it is important to inspect the bags for any signs of wear or damage before reuse.

2. Are ESD moisture barrier bags suitable for long-term storage? Yes, ESD moisture barrier bags are designed for long-term storage, providing protection against both electrostatic discharge and moisture during extended periods.

3. Can ESD moisture barrier bags be used in humid environments? Yes, ESD moisture barrier bags are effective in humid environments as they offer moisture barrier properties. However, it is crucial to ensure proper sealing to maintain the bag’s effectiveness.

4. Are ESD moisture barrier bags recyclable? The recyclability of ESD moisture barrier bags depends on the specific materials used. Some bags may be recyclable, while others may require specialized recycling processes. Check the bag’s specifications or consult the manufacturer for recycling information.

5. Can ESD moisture barrier bags be used for shipping electronic components? Yes, ESD moisture barrier bags are suitable for shipping electronic components as they provide protection against both electrostatic discharge and moisture during transportation.

Related Products:

continue reading