Cleanroom products are specialized equipment, materials, and supplies used in cleanroom environments to maintain strict cleanliness standards and prevent contamination. Cleanrooms are controlled environments designed to minimize the presence of airborne particles, dust, microorganisms, and other contaminants that could adversely affect sensitive processes or products. Here are some common cleanroom products:

Sticky mats, rollers, cleanroom wipes, cleanroom swabs, shoe cover dispensers, non-woven products, DCR-pads/face masks, and cleanroom printing paper/notebooks are specialized products used in cleanroom environments to maintain cleanliness and prevent contamination. Here’s a brief overview of each of these products:

- Sticky mats: These are adhesive mats that are placed at the entrance of a cleanroom to remove dirt and debris from shoes and carts before entering the cleanroom.

- Sticky rollers: These are adhesive rollers used to remove particles and debris from surfaces and equipment in a cleanroom environment.

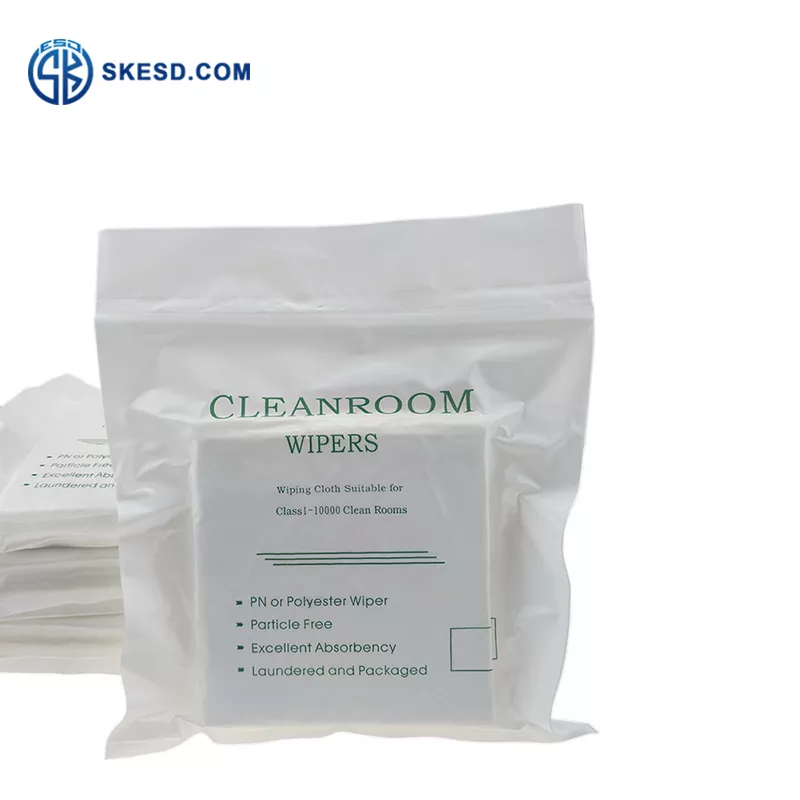

- Cleanroom wipes: These are specialized wipes made from non-linting materials used to clean and disinfect surfaces and equipment in a cleanroom environment.

- Cleanroom swabs: These are specialized swabs made from materials that will not shed fibers or particles. They are used to clean hard-to-reach areas in a cleanroom environment.

- Shoe cover dispensers: These are machines used to dispense shoe covers to workers entering a cleanroom, ensuring that no outside contaminants are brought into the room.

- Non-woven products: These are specialized products made from non-woven materials, such as face masks, bouffant caps, and gowns. They are used to protect workers and products from contamination in a cleanroom environment.

- DCR-pads/face masks: These are specialized products used to protect workers from exposure to hazardous chemicals or particles in a cleanroom environment.

- Cleanroom printing paper/notebooks: These are specialized paper and notebooks made from non-shedding materials for use in a cleanroom environment.

Using these specialized products can help maintain cleanliness and prevent contamination in a cleanroom environment, ensuring product quality and worker safety.

Rohs 2.0 has emerged as a crucial aspect of compliance […]

In today’s fast-paced world, fatigue is a common concern for […]

In laboratory environments, safety and productivity are of utmost importance. […]